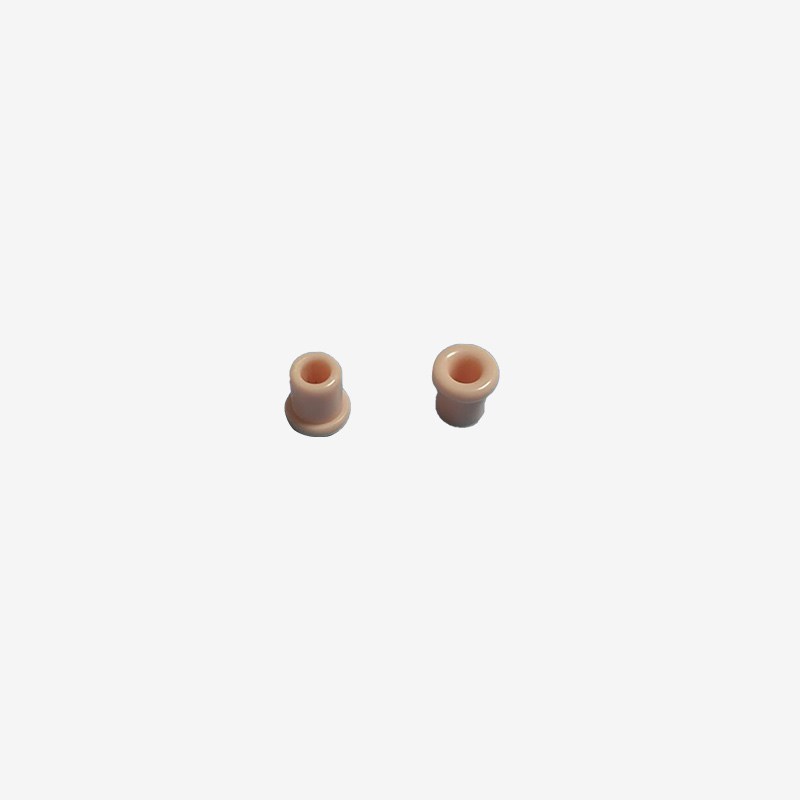

Inxalenye ye-Alumina yeCeramic yoomatshini beTelephu

Indawo yosetyenziso

Izahlulo zeseramikhi zelaphu ezisetyenziswa ngokubanzi koomatshini belaphu abanepropathi ephezulu yomatshini, ubulukhuni obuphezulu, ukunxiba ixesha elide, ukuxhathisa okukhulu kokugquma, uthintelo olulungileyo lokutya, ukumelana nobushushu obuphezulu.

Iinxalenye ze-textile ze-ceramics zinoluhlu olubanzi lwezicelo kubomi bemihla ngemihla.Sithi iinxalenye ze-almunia ceramics zingasetyenziswa kwiinkqubo ezinje ngokudibanisa intambo, ukuzoba, ukusonta, ukwenza iplastiki, ukuluka, ukunitha njalo njalo.I-China yeyona ntengiso inkulu yezahlulo zeseramikhi zelaphu.Ukongeza, ishishini lezixhobo ze-ceramic ezikhuphisanayo zasekhaya lihlala litshintsha.

Amanye amashishini asekhaya athe ngokuthe ngcembe acutha umsantsa kunye neempawu zangaphandle ngophando lwetekhnoloji kunye nophuhliso kunye nokuphuculwa komgangatho, kwaye isabelo sabo sentengiso siye sanyuka kancinci.Kwangelo xesha, ezinye iibrendi zangaphandle ziye zangena ngokuthe ngcembe kwimarike yaseTshayina, ziqhubela phambili ukukhuthaza ishishini lezixhobo ze-ceramic.

Iinkcukacha

Ubungakanani obufunekayo:I-1pc ukuya kwi-1 yezigidi zeepcs.Akukho MQQ ilinganiselwe.

Ixesha lesampula lesampulu:ukwenza izixhobo yi-15days + isampuli yokwenza 15days.

Ixesha lemveliso:15 ukuya 45days.

Ixesha lokuhlawula:uthethathethwano ngamaqela omabini.

Inkqubo yokuvelisa:

I-Alumina(AL2O3) i-ceramic yi-ceramic yoshishino enobunzima obuphezulu, ukunxiba ixesha elide, kwaye inokwakheka kuphela ngokusila idayimani.Iveliswa kwi-bauxite kwaye igqitywe ngokubumba, ukucofa, ukucwina, ukucola, ukuthunga kunye nenkqubo yokwenza.

Idatha yePhysical & Chemical

| I-Alumina Ceramic(AL2O3) iPhepha leNgcaciso yoMlinganiswa | |||||

| Inkcazo | iyunithi | IBakala A95% | IBakala A97% | IBakala A99% | IBakala A99.7% |

| Ukuxinana | g/cm3 | 3.6 | 3.72 | 3.85 | 3.85 |

| I-Flexural | Mpa | 290 | 300 | 350 | 350 |

| Amandla acinezelayo | Mpa | 3300 | 3400 | 3600 | 3600 |

| Imodyuli ye-elasticity | Gpa | 340 | 350 | 380 | 380 |

| Ukuchasa impembelelo | Mpm1/2 | 3.9 | 4 | 5 | 5 |

| Weibull modulus | M | 10 | 10 | 11 | 11 |

| Vickers hardulus | Hv0.5 | 1800 | 1850 | 1900 | 1900 |

| I-coefficient yoKwandiswa kweThermal | 10-6k-1 | 5.0-8.3 | 5.0-8.3 | 5.4-8.3 | 5.4-8.3 |

| I-Thermal conductivity | W/Mk | 23 | 24 | 27 | 27 |

| Ukunyangwa kwe-Thermal shock | △T℃ | 250 | 250 | 270 | 270 |

| Ubushushu bokusebenzisa okuphezulu | ℃ | 1600 | 1600 | 1650 | 1650 |

| Ukumelana nomthamo kwi-20℃ | Ω | ≥1014 | ≥1014 | ≥1014 | ≥1014 |

| Amandla e-Dielectric | KV/mm | 20 | 20 | 25 | 25 |

| I-Dielectric rhoqo | er | 10 | 10 | 10 | 10 |

Ukupakisha

Ngokuqhelekileyo sisebenzisa izinto ezifana nobungqina bokufuma, ubungqina bokuthuthumela kwiimveliso ezingonakali.Sisebenzisa ibhegi yePP kunye neepaliti zeplanga zebhokisi ngokwemfuno yomthengi.Ilungele ukuthutha elwandle kunye nomoya.